2011 Spring Meeting

Carlos Claros of MWH Americas presented a succinct summary of the benefits of anaerobic treatment for high strength COD/BOD (organic) loaded wastewater streams. In industry, about 65% of the successful applications have been in the food, food and animal processing, agricultural, and beverage industries.

Referring to the level of organic loading, low-rate anaerobic treatment is often accomplished in treatment lagoons. Medium-rate streams are effectively treated in CSTRs and various forms of contact (fixed film) treatment, such as bio-wheel types. High-rate systems include up-flow sludge blanket systems, expanded granular sludge bed systems and internal circulation reactors.

The Good...

The advantages of anaerobic treatment systems over their aerobic counterparts include:

- Generation of beneficial biogas

- Low energy consumption

- Low sludge creation, up to 10x less than aerobic processes

- Low process space requirements

- Lower capital and operation/maintenance costs

Anaerobic treatment has a strong position in the biofuels industry too. Many corn ethanol plants have an expanded bed bio-reactor, or specialized anaerobic treatment train on their wastewater streams. Also, most of the new cellulosic ethanol process based on acidic digestion will have need of an anaerobic treatment system.

...The Bad...

Some disadvantages to straight anaerobic systems, and potential remedies, are listed below:

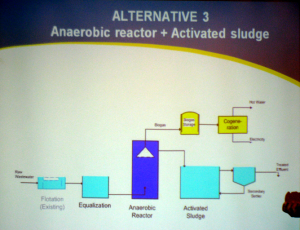

- Only 80% COD removal is achieved---adding an aerobic digester following as a lower power consuming "bio-polisher"

- Long culture startup times---use of acclimated seed cultures may alleviate this problem.

- Sensitive to influent conditions variability---adding equalization tanks can even out upstream process fluctuations.

- Low metabolic rates at low temperatures---waste heat can be added to the system.

....And the Ugly

There are some specific constituents that can wreak havoc in an otherwise well-designed anaerobic upflow or internal circulation reactor system. First of all, high sulfates in the wastewater are a problem as they are converted to sulfides (often hydrogen sulfide) which at concentrations above 200 ppm become detrimental to microbe metabolism (and the sensibilities of the neighbors, too). In addition, the organisms can experience cation toxicity, with high levels of sodium, potassium or other cations. The best solution to these problems is elimination or segregation.