By: Joseph Grimaldi (RPI)

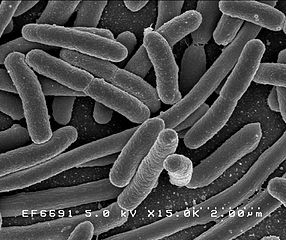

The current method for producing alcohol biofuels, in particular butanol, is through metabolic cellular processes.1 Clostridia species are used to produce butanol, but they are not very suitable because they are complex and not well understood.2 Biological pathways have also been developed for strains of Escherichia coli and Saccharomyces cerevisiae;2-3 both of these microbes have better genetic tools available.

There are some advantages for using a cell-based system. All the enzymes needed to produce the product are synthesized and retained inside the cell.1 The product is also secreted from the cells, so cell lysing is not needed to obtain the butanol. 4

There are disadvantages to having an in vitro system. There is extensive time spent working through system biology.3 Clostridium produces butanol/acetone/ethanol in a 6:3:1 ratio.4 The bigger issue is with yield.1 When the concentration of alcohol in the media becomes too high, it starts to kill the cells.2 The highest reported in vitro yield is 13 g/L of butanol in water.2 In comparison, the solubility of butanol in water at room temperature is 77 g/L.

References