This post is presented by SBE, the Society for Biological Engineering--a global organization of leading engineers and scientists dedicated to advancing the integration of biology with engineering.

With surging, nationwide shale-gas drilling, natural gas prices have plummeted, prompting utilities to rely on domestically produced fuel even more; meanwhile, some have also begun to switch away from coal, a major infrastructure pivot, to pump out base-load power. But as demand has jumped to record levels, supplies are now growing so fast that prices and profits have remained stubbornly low. So in mid-July, Chesapeake Energy, the second-largest producer of natural gas in the U.S. (popping $3 million a year to vanity-plate an NBA basketball trophy-arena) launched a $1 billion venture fund to invest in technologies designed to spur demand while also helping to replace dependence on foreign oil. The new fund would be financed by diverting 1 to 2 percent of the company's annual drilling budget. Within weeks, energy columnist Kirsten Korosec, who writes Carbon Based, sniffs a trend and reports two quick deals. Obviously, Chesapeake had been kicking the alt-fuel tires awhile.

Chesapeake has agreed to invest $150 million into Clean Energy Fuels Corp., a company founded in 1996 by Texas billionaire T. Boone Pickens, to accelerate its build-out of liquified natural gas fueling infrastructure for heavy-duty trucks.

Building natural gas infrastructure to create more end-users is a no-brainer, but Chesapeake's second investment is more ambitious: a natural-gas-to-liquids "play" (jargon watch). Korosec explained:

The company will also invest $155 million in a 50 percent ownership stake in Sundrop Fuels, a small, former solar/cellulosic biofuels company... [the investment] will be used over the next two years to build a nonfood biomass-based "green gasoline" plant capable of producing 40 million gallons of fuel a year.

Key words are "former solar," and a surviving, luminous mandala logo--very BP, and very ambitiously beyond BP. But now, Sundrop's former solar gasifiers will be natural gas powered--the ruthlessly pragmatic evolution of a new business and its nascent technology. Kid, you're leaving your family, friends and old uncle Joe in Solar-Farmville and entering Synergy-City--enjoy your stay, energy mogul. This is win-win for Chesapeake. If successful, plants would be rolled out all over the country, hoovering up natural gas and biomass, and propping up prices and improving revenues. For Sundrop, with a major energy company throwing so much cash at the fragile, new concept, the change from solar to low-priced natural gas hyper-shifts a stalled build-out.

What a short, strange trip it's been

The changes have happened quickly--just like the precipitous drop in natural gas prices. (It's no coincidence that two former GULF LNG facilities are currently being converted to supply exports instead of imports.) Just a little over a year and a half ago, Sundrop Fuels, while emerging from stealth mode, touted its new concentrated solar concept to Technology Review's Tyler Hamilton, who, dazzled by the CSP approach, wrote:

A startup based in Louisville, CO, says it has developed a cleaner and more efficient way to turn biomass into synthetic fuels by harnessing the intense heat of the sun to vaporize wood and crop waste.

Sundrop's original elevator pitch: a unique solar play, nothing like traditional gasification with heat normally coming from a substantial portion of the converted biomass. "You end up burning 30 to 35 percent of the biomass," said Alan Weimer, chemical engineering professor and company co-founder. In a new Sundrop fuel gallon, 30 percent of the energy is solar, while the remainder is biomass. Several years earlier--long before stealth mode, when natural gas was much more expensive--Weimer and his university research team had begun looking for a cheaper, more eco-friendly heat source. Experimenting, they tried driving the gasification process with concentrated solar heat. The results were so impressive, Weimer went on to cofound Copernican Energy. Shortly after, Copernican was acquired by Sundrop Fuels in 2008, its solar-reactor technology the centerpiece of a small 1.5-megawatt gasification demonstration in Colorado.

The original concept was solar-centric

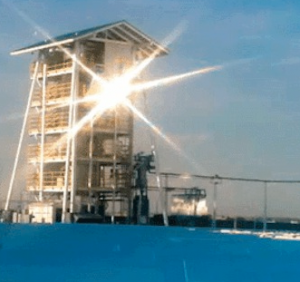

Then, while in top secret super stealth mode, the proprietary solar-thermal gasifier was mounted on top of a tower surrounded by a field of solar mirrors reflecting sunlight at the furnace. Inside the gasifier--which was deliberately kept biomass "agnostic"--feedstock dropped through hot ceramic tubes and instantly vaporized into syngas. Weimer colorfully emphasized, "It's like a sledgehammer because of the (1200 to 1300?C) operating temperatures." And because conventional methods that use temperatures below 1000?C to minimize the biomass loss left behind tar, Weimer, probably with an arched professorial brow, explained, "If you leave it in there, it will end up killing your catalysts downstream when you try to reform your product into fuel. And that tar is expensive to remove." It turned out that higher temperatures also make a better quality syngas. Conventional gasification typically produces a syngas mixture that's half hydrogen and half carbon monoxide. Sundrop's original process, which also pumped in some natural gas, achieved a hydrogen-to-CO ratio of two to one.

"I can tell you, the economics have been looked at quite extensively, and the idea of being able to produce gasoline at less than $2 a gallon without subsidies, we believe that's a real number," Weimer said. But the company didn't underestimate the challenges, freely acknowledging that most biomass resources aren't located near the intense sun required for concentrated solar. Still, some woody biomass did exist in the U.S. Southwest, where Sundrop planned to build its first commercial plant. Sundrop was also already looking into transporting switchgrass by rail from as far north as Kansas and as far east as Texas. Essentially, Sundrop had a great concept, but it was also one that hindered widespread expansion. They were already looking at comparable solar-profiles in Spain, ignoring the American midwest's 'spacious skies, for amber waves of grain..."

After the Chesapeake hookup, good morning starshine

The company plans to break ground on the commercial scale biorefinery in 2012. When construction is complete, the facility will be capable of producing 40 million gallons of transportation fuel a year, making it the largest nonfood bio-based "green gasoline" plant in the world.

But there will be no surrounding mirrored array. Sundrop's earlier focus on solar is gone. The gasifier is now called a "radiant particle technology," meaning the company isn't relying on solar as the main source of its heat. Sundrop's own website makes that clear: "We can use clean-burning natural gas, electricity or even concentrated solar to power the RP Reactor, which by maintaining ultra-high temperatures ensures the most efficient use of biomass feedstock." Essentially, it will be powered by natural gas and finely ground cellulosic biomass material.

Fortunately, energy-source and biomass flexibility will allow Sundrop Fuels to locate in the most economically and environmentally efficient areas of the country to produce millions of gallons of drop-in biofuels per year. The biorefinery is fully integrated, its reactor technology producing syngas converted to methanol and then, finally, using ExxonMobil's patented methanol-to-gasoline process, turned into "green" gasoline. By 2016, the company hopes to have a 200-million gallon per year biorefinery up and running. And as clean-energy purist Tyler Hamilton plaintively concluded:

...the company wants to mix biomass and natural gas together. What this tells me is that it's most interested in the final refining process, which turns natural gas or syngas or a mix of both into "green" gasoline.

Let's look at the big picture. A pragmatic, flexible foot in the biofuels door--with the production of hundreds of millions of gallons--is a strong contribution toward America's fuel independence.

Comments

Its not exactly gas powered, the energy of the furnace is still concentrated solar. Adding natural gas to the mix allows steam reforming to occur which produces a better synthesis gas mix for the methanol reactor.

Thanks for clearing that up.