The U.S. is highly dependent on foreign countries for rare earth elements (REEs) and strategic and critical materials (S&CMs). This dependency has the potential to negatively impact the U.S. manufacturing industry, energy supply, and national defense should natural sources deplete or foreign relationships deteriorate. For example, the largest consumers of REEs in the U.S. are catalyst manufacturers, representing almost 30% of the domestic market by volume in 2008. Over 95% of the worlds REE supply is mined in China. If China restricts exportation of REEs in the near future, the economic impact could have dire consequences on the U.S. chemical industry. Typically, S&CMs and REEs are acquired through mining. Low labor standards in some of the nations that mine critical materials create ethical concerns for consumers. The steps involved in extraction and processing produce emissions and pollutants that harm the environment. At the end of their lifespan, many of these materials are disposed of in landfills, causing further environmental damage.

Urban mining and recycling

Dr. Tedd Lister and Dr. Eric Peterson of the Idaho National Laboratory propose "urban mining" to address the concerns associated with traditional mining. In urban mining, expended consumer products are harvested, dismantled, and processed to regain and thus recycle critical materials. Urban mining deposits are much richer than primary ore bodies; there are a massive number of consumer products such as mobile phones and laptops that contain small amounts of S&CMs, including silver, gold, and palladium. When combined, these small amounts represent a large volume of untapped critical materials.

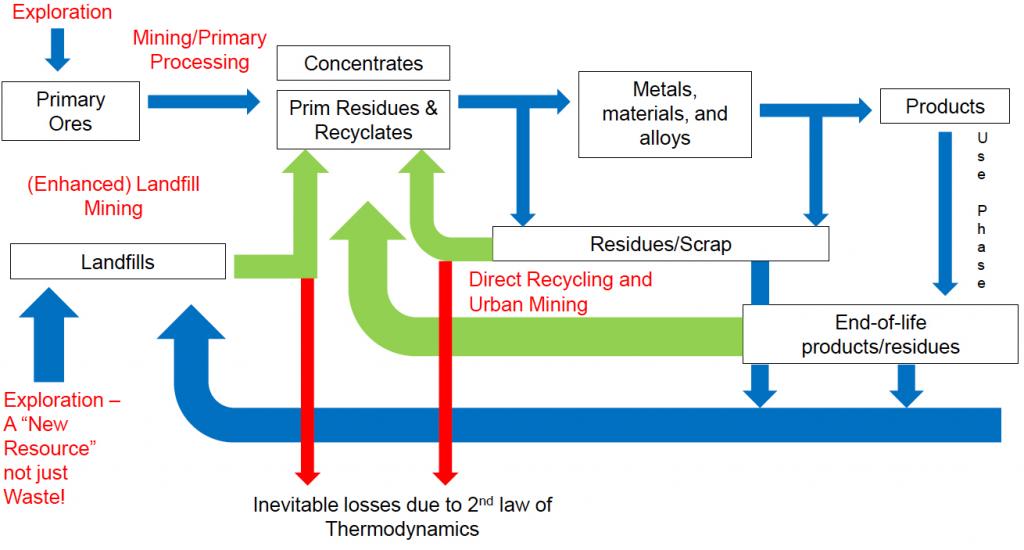

In the lifecycle loop shown, the green arrows represent urban mining. Critical materials are harvested from scraps from production processes, landfills, and end-of-life consumer products. Closing the lifecycle loop could significantly reduce traditional mining. Urban mining mitigates the environmental impacts of traditional mining; it also consumes less energy and reduces land use for landfills. The amount of materials that can be recycled is vast, and urban mining has the potential to create a much more sustainable reliance on S&CMs.

Challenges to further development

There are several barriers to closing the lifecycle loop on critical materials. Recycling technology is costly and needs development before full market deployment is possible. Consumer products are difficult to dismantle, and individual element separation is often a challenge. Despite these obstacles, potential economic and ethical advantages warrant the full exploration and development of urban mining and recycling.

Comments

There are far too many barriers to recycling - especially electronics. It is difficult for consumers to find the correct place to return the products and it is often difficult to return them. And with current production methods, retrieving these metals is also difficult. I would think there should be a way to design the products to make it easy to disassemble - then the manufacturers would have an incentive to get customers to return the products as a source of fresh raw materials. It could even promote brand loyalty.