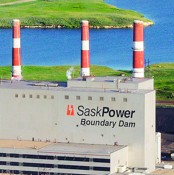

Carbon capture and storage (CCS) remains stubbornly expensive. Which is why so many projects have been aborted in the last few years, left stumping for research dollars in government-matching-funds limbo. Still, companies have been working hard to shrink costs and find new revenue streams. Finally, SaskPower, the provincial utility of Saskatchewan, Canada, is ready to fire up the world's first commercial-scale, clean-coal power plant that captures post combustion carbon dioxide. (You can watch the company promo video here.)

While many environmental groups vehemently fight the idea of clean-coal technology, others see it pragmatically, as helping countries hit ambitious emission reduction targets. This becomes especially crucial since global coal consumption in 2020 will double from levels in 2000 and grow for decades afterward, according to the Energy Information Administration (EIA). SaskPower didn't build this technological marvel altruistically or voluntarily. The utility had been looking at new regulations that required all coal-burning power plants over 50 years old either to shut down or convert to emitting just 420 tons or less CO2 per GW-hour by July 2015. Each unit of the company's six-unit Boundary Dam power plant would have spectacularly overshot the cap.

Dead man walking

In today's regulatory environment, a 45-year-old coal-fired power plant is a dead man walking. Located on the desolate plains of Saskatchewan, Canada, which already feels a bit like solitary confinement, Boundary Dam's unit 3, which emits a flagrant 1 million tons of carbon dioxide a year, was singled out to get the ax. (Which turned it into more of a demonstration project.) Originally, SaskPower had decided to replace Unit 3 with a 300MW gas-powered turbine, which seemed reasonable at the time, but after projected construction costs ballooned to $3.8-billion, the choice shifted to natural gas versus sticking with coal retrofitted with CCS - a rehabilitation of sorts. So although the price of gas was low at the moment, and the capital costs of a coal-fired power plant with CCS would be more than a gas-fired plant, the unpredictability of future gas prices pushed the SaskPower executives back to coal. Weighing heavily on the decision were the company's large, nearby coal reserves, profits from piping the recovered gas to a local EOR site, and $240 million in government backing. At the time, the government minister overseeing SaskPower said Saskatchewan had to develop CCS technology because it had 300 years' worth of coal reserves and relies on it for much of its electricity. SaskPower spent $1.24 billion (600 million going for CCS) modernizing the plant. Fully operational in October, it will capture 1 million tons per year of CO2 - bout 95% - and have a 110 MW generating capacity. "The resulting power will be some of the world's most environmentally clean power from fossil fuels," SaskPower's CEO Robert Watson told the New Scientist. To do the job, exhaust from a power plant is passed through a regenerable solvent where a proprietary amine captures the CO2 from the flue gas. The carbon dioxide is finally pulled away and released as a pure stream. Then it will be sold and piped to a nearby oilfield owned by Cenovus, a Canadian oil company, and used in enhanced oil recovery to increase production.

Desperate for scarce gas

It turns out that CCS and enhanced oil recovery will have a very symbiotic relationship. Since prices for US crude oil have been high for a long time, carbon flooding has become a very profitable business. Even though fracking produces eight times more total crude oil, output from enhanced oil recovery should grow 3.6 percent annually for at least 25 years, compared to just 1.3 percent for shale. "Everybody's always talking about shale, but carbon flooding is going to be a growth business for us," Jeff Simmons, chief of Occidental's Permian Basin unit, told Bloomberg. But such rapid growth has created a scarcity of CO2. Oil producers in the Permian are using all the natural CO2 they can get. "There are millions and millions of barrels of oil waiting to be unlocked, said Darrell Ricketson, VP of Kinder Morgan Energy Partners Permian Basin CO2 floods. "It's not as widespread as it could be because of the limited availability of CO2." It's estimated that there are 160 billion barrels of recoverable oil that can now be brought to the surface with an assist from CO2, potentially bringing in a gusher worth $17 trillion.

Valuable intellectual property

SaskPower is counting on another revenue stream. The company owns the intellectual property to the CCS project and wants to sell it. CEO Watson says, "We have lots of interest with big companies around the world," naming China, Japan, UAE, Germany and others. He also insists that new CCS plants could be built for a third less than SaskPower's. This is new paradigm not just for SaskPower but for the global power industry, and carbon flooding companies are anxiously waiting see a surplus of CO2 - but underground, pushing oil to the surface.