Since the origination of membrane processes in water purification, the focus has always been Reverse Osmosis (RO). Although this has the advantage of being a "one-unit ops" process to create pure water, the capital and operating costs in the high-pressure pumps required to combat the osmotic pressure, and the cost of preventing and/or recovering from membrane fouling are high.

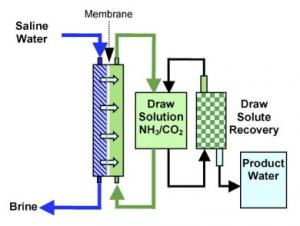

Forward Osmosis (FO) offsets some of these high costs, but large-scale systems necessarily introduce one or more additional unit ops to recover the extracted water from the draw solution utilized. Young Kim of the Korea Institue of Machinery and Materials (KIMM) discussed her work on the construction an FO pilot plant, and some of the successes and remaining challenges of an industrial-scale FO system.

Forward osmosis concepts and the draw solution

The phenomenon of osmosis is characterized by the movement of solvent (water, typically) across a semi-permeable membrane from a dilute to a more concentrated solution. Without the membrane, the solute(s) would diffuse into to the more dilute solution to allow for equalization of free energy. However, since the membrane doesn't allow the solute to diffuse, the solvent moves in the opposite direction to equalized the energy state. In reverse osmosis, energy (pressure) is applied to drive the water in the opposite direction, allowing the membrane to provide the "de-soluting," and resulting in purified water.

In forward osmosis, the water moves through the membrane from the stream to be "purified" into a prepared solution of greater ionic strength. This prepared solution is called the draw solution, as it draws the water through. But how does it help to draw purified water into a concentrated solution? In two possible ways:

- If, for example, the draw solution is a very concentrated solution of electrolytes and sugars, the FO process essentially provides clean water for dilution of a nutritious hydrating drink for human consumption. This approach is already in limited practice for emergency "rations" and disaster relief supplies, on a per-person/family up to a per-community/village scale.

- In order for FO to be utilized for pure water preparation, the water that is drawn needs to be able to be recovered from the draw solution, and the draw solution reused. This approach is under study at KIMM.

Pilot plant design

The FO module was comprised of off-the-shelf 4" x 40" cellulose acetate (CA) membranes from HTI, providing an effective membrane area of 3.3 m2. At the target flux rates (dictated by the "sea-water" and draw solution concentrations) the system could produce (pass) about 500 L/day.

A train of three membrane modules in series was used. Series flow was utilized to maximize retention time and water recovery. The pilot system is configurable for testing cross-flow and counter-current flow options also. The flow configuration was with the draw solution recirculated in the core and synthetic sea water in the annular spaces.

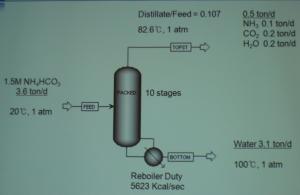

The synthetic sea water was 0.55 M NaCl, and trials using draw solutions of ammonium bicarbonate at 1.0, 1.5, and 2.0 M were used. Both a membrane and packed column distillation system pilot were constructed, with performance data from the 10-stage atmospheric column reported.

Ammonium carbonate draw solution

Key to the effective use of FO for desalination is use of a draw solution that has high osmotic pressure (strong driving force) and is readily separable to allow for energy efficient water purification from the draw. As you might expect, this latter challenge is the challenge in FO desalination.

Part one of the recovery process is a packed column distillation, with a 60% ammonium bicarbonate stream recovered in the "tops" and pure water in the bottoms. Preliminary results indicate a difficulty in obtaining the purity necessary due to the high solubility of ammonia in the water stream.

The reabsorption of the solutes has proven even more of a challenge. Getting the CO2 back in solution as carbonate has been very difficult, with excessive water used and only 60% recovered. Indeed, there appears to be an inverse or competing process whereby the greater the carbon dioxide recovery, the less the ammonia, and vice versa.

Issues and future work

Work to develop a suitably efficient process of water purification and draw solute recovery is paramount. Without it, FO will be limited to Type 1 applications, as described above. Work focuses on both ammonium bicarbonate process improvements and alternate/modified solute systems. Another issue discovered was the apparent instability of the CA membrane to the draw solution. Alternates membranes, coatings and double-sided membrane systems are in consideration for addressing this issue.