Just over a year ago, Deeya Energy, a startup responsible for flow battery backup systems for cell phone towers in India, renamed itself Imergy Power Systems, hired a new CEO and threw out its iron-chromium battery chemistry, replacing it with the more-expensive vanadium. This seemed a little crazy at the time, a Solyndra flameout that should cripple the Fremont, California, company and batter its investors.

Even though vanadium provides more power and energy than other electrolyte metals (zinc bromine, iron chromium), if you're a vanadium flow battery CEO, you'll ruin your day just by checking the metal's volatile price, which makes up about 40% of each battery's cost. It's a tiny niche in a market dominated by the global steel industry, which sucks up 90% of demand by adding a small amount of vanadium to strengthen every piece of steel rebar used in concrete for buildings, bridges, and roads.

The new electrolyte solved another bottleneck: the old battery worked optimally between a narrow range of 10 to 40 Celsius. Colder, the electrolyte crystallized. Overheating rendered the battery useless. Now the battery worked at temperatures between -40 degrees and more than 50 degrees Celsius, making it reliable around most of the world. Air conditioners could be now junked, which trimmed a 20 percent energy loss. "When you eliminate both the hydrogen bubbling and the expensive cooling system, we can (more cheaply) operate in places like India," says Watkins. "There is no other flow battery that can do that." About 50 of the new units have already been successfully tested in India's hot, dry climate.

A breakthrough

There was a carry-over drawback with the new PNNL electrolyte. It still required pure vanadium, making the batteries 50 percent more expensive than iron-chromium. But Imergy completely remade the playing field when co-founder and chief technology officer Majid Keshavarz altered the electrolyte to accept lower-grade vanadium extracted from iron ore waste, oil sludge, or fly ash from coal-powered power plants.

Any company using pure vanadium must process it to an exacting 99% level of purity, but Keshavarz's new electrolyte requires only a 98% purity level. That single percentage point moves the cost spread between pure vanadium and Imergy's scavenged metal about 30%, giving it a stronger competitive advantage. Imergy now says it will be able to lower the cost of its flow batteries from $500 a kilowatt hour to about $300 per kilowatt hour and hopes to have new batteries on the market by 2015. New factories in California and India should drop the costs even further. "We think we can go commercial for under $300 per kilowatt-hour," Watkins says. Since Watkins was brought in to rapidly scale up the company, he plans to take the new technology beyond the current Indian cell tower installations and conquer larger and much more profitable markets.

Let the battle begin

Imergy wasn't the only vanadium battery maker to take advantage of the new PNNL electrolyte. UniEnergy, a younger startup based near Seattle Washington, also licensed it. And it shouldn't be a surprise that its co-founders, CEO Z. Gary Yang and CTO Liyu Li, are the same PNNL scientists who developed the new electrolyte and jumped on a good thing when they created it. Eventually, they'll be competing head-to-head with Imergy and against their own ingenuity.

While Imergy is still working with contract manufacturer Flextronics on its prototype, two-year-old UniEnergy is already bringing its vanadium flow battery to market. One of its main investors, Dalian Bolong Holding Co of China, which owns a large vanadium miner and Rongke, a company that's made vanadium flow batteries for eight years, knew about Yang and Li's work. Dalian executives were eager to help the two researchers spin off their disruptive idea. Assured of a steady and inexpensive supply of vanadium, UniEnergy also mined Rongke's experience to design the 600-kilowatt, 2-megawatt-hour energy storage system it's now sending into the field. The startup also got a boost stateside when it won two installations from local Washington utilities, as the state brands itself as a center for new energy storage technologies. In fact, the startup plans to install a total of 3.5 megawatts of batteries this year, which includes 2 megawatts for the home-state Snohomish utility, 1 megawatt at another Pacific Northwest utility, and an additional 500-kilowatt system in California. With its spacious 67,000-square-foot factory, the startup plans to manufacture 18 megawatts next year and could produce up to 100 megawatts a year.In the end, Imergy's Watson spoke for both companies when he told Greentech Media, "At the end of the day, it's all about hitting cost points and whether you have a technology platform that allows you to scale. We can take the chemistry and technology within the flow battery and extend it." Let the battle begin.

When will these two companies end up competing?

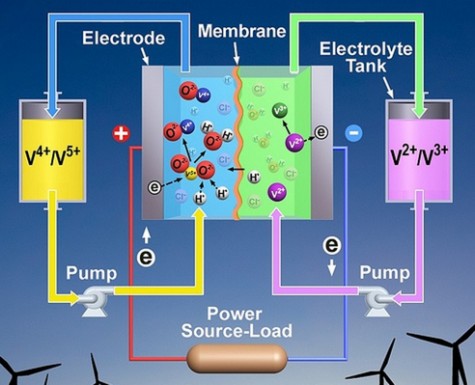

Images: Imergry battery, Imergy video; flow battery schematic, PNNL; grades of vanadium, Alchemist-hp pse-mendelejew.de; UniEnergy batteries, UniEnergy