A new direction: fuel cells yield exciting results

Now, in a departure from pyrolysis, Huber has developed a continuous process for converting biomass and electricity into renewable liquid transportation fuels, using fuel cells. "It's what we call electrofuel," said Huber. A paper on the work was published in the journal

ChemSusChem.

The technology, he said, creates a "renewable liquid fuel that fits into the existing petroleum infrastructure." Unlike other technologies that use large quantities of expensive hydrogen gas to convert biomass to biofuels, the team's process is driven by electricity. "We're storing the electrical energy as chemical energy," said Huber.

"The advantage is, wherever you have cheap biomass and you have electricity, you could use this technology," Huber told Wisconsin

JSOline. Electricity would be used during nonpeak hours when the wholesale price of power is less expensive.

Normally fuel cells convert chemical energy into electrical energy, but Huber reversed the process, reconfiguring it to convert the model biomass compound acetone into isopropanol, with a wide variety of pharmaceutical and industrial applications, including as a gasoline additive.

Since reactions in a proton-exchange-membrane fuel cell require only water, electricity, and biomass to reduce biomass molecules into fuel, Huber's team feeds water into the anode side and passes an electric current through the water to generate protons and electrons. The electrons run through a circuit and the protons pass through the proton-exchange membrane to the cathode side, where they generate hydrogen. The hydrogen reacts with the biomass molecule and reduces it to fuel, while oxygen exits the system.

The process yields 50 percent more liquid fuel over ethanol fermentation processes.

The advance paves the way for researchers to convert biomass molecules such as glucose into hexanes, which are significant components of gasoline currently derived by refining crude oil. In this interview he describes his progress to

Chemistry Views:

At the production level, the new process also could be modular, says Huber. "This is potentially a scalable technology where you could make these proton-exchange-membrane-type reactors in the field, close to the biomass."

Always looking to the future, Huber concludes: "It's an exciting time to be in the field of chemistry catalysis. With high oil prices and environmental challenges, there's lots of opportunity for advances to develop these new processes."

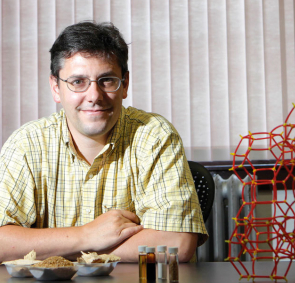

Almost since he began studying chemical engineering, George Huber, UMass Amherst professor of chemical and biological engineering, has had an ambitious vision: to make all the same fuels and chemicals from biomass that we make today from crude oil.

As he quickly moved beyond first generation feedstocks like corn and focused on lignocellulosic biomass - woods, grasses, and inedible stalks of plants - he became a "pyromaniac," specializing in catalytic technologies.

Almost since he began studying chemical engineering, George Huber, UMass Amherst professor of chemical and biological engineering, has had an ambitious vision: to make all the same fuels and chemicals from biomass that we make today from crude oil.

As he quickly moved beyond first generation feedstocks like corn and focused on lignocellulosic biomass - woods, grasses, and inedible stalks of plants - he became a "pyromaniac," specializing in catalytic technologies.

Huber's patented, single-step, catalytic fast pyrolysis process, biomass was fed into a fluidized-bed reactor, where it thermally decomposed into vapors, which then entered the zeolite catalyst - also inside the same reactor - to be immediately converted into the desired chemicals.

In a 2008 paper in the journal ChemSusChem, Huber and his colleagues reported that the entire process was completed in under two minutes, and the liquid could be further treated and used for high octane gasoline. He explains the original process

Huber's patented, single-step, catalytic fast pyrolysis process, biomass was fed into a fluidized-bed reactor, where it thermally decomposed into vapors, which then entered the zeolite catalyst - also inside the same reactor - to be immediately converted into the desired chemicals.

In a 2008 paper in the journal ChemSusChem, Huber and his colleagues reported that the entire process was completed in under two minutes, and the liquid could be further treated and used for high octane gasoline. He explains the original process