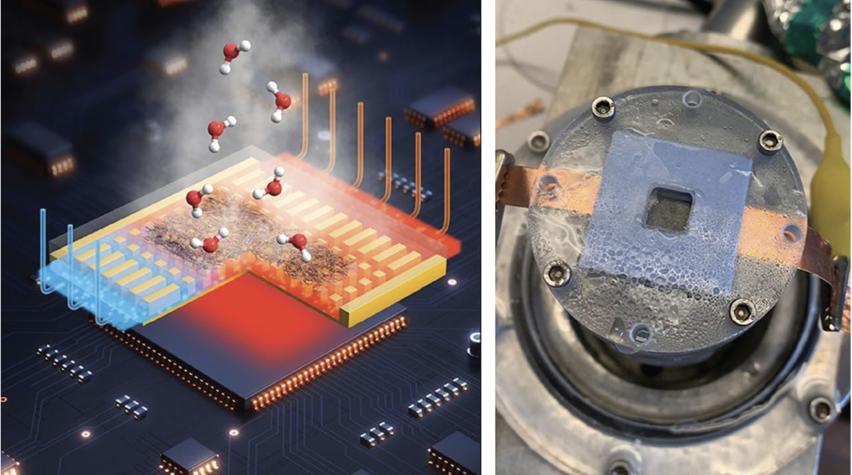

Above: Evaporative cooling systems hold promise for use in the data centers that run large language models (LLMs) and other artificial intelligence (AI) systems. A team of researchers tested different glass fiber membranes for their effectiveness in removing heat from electronic chips (left). At right, the evaporation test setup of the fiber membrane is shown. Images courtesy of Tianshi Feng and Yu Pei.

Glass fiber membranes, typically used in water and air filters, could be the key to cooling off the data centers that run large language models (LLMs) like ChatGPT and other artificial intelligence (AI) systems.

High energy load

AI and other high-intensity computing applications are energy-hungry. A 2024 Dept. of Energy report found that data center energy load had tripled over the previous decade and was expected to double or triple again by 2028. As of 2023, data centers accounted for 4.4% of the electricity consumed in the U.S., that report found, with an expected increase of up to 12% of U.S. electricity by 2028.

Cooling

The graphics processing units (GPUs) and central processing units (CPUs) in data centers are currently cooled either by air-based cooling systems that run cool air between racks, or by single-phase liquid cooling. In single-phase liquid cooling, a coolant is circulated inside a cold plate that sits next to the electronic equipment. These methods can account for up to 45% of a data center’s electricity requirements. And they’re not enough, adds Renkun Chen, a professor of mechanical and aerospace engineering at the Univ. of California, San Diego.

“If you look into the near future, just a few years from now, this solution will not be adequate in terms of matching the heat flux of these electronic devices,” Chen says.

Traditional technologies can typically handle a heat flux of up to about 100 W/cm2, which modern electronics are already hovering around. For example, NVIDIA’s Hopper GPU has a thermal design power of 700 W on an 814-mm chip, translating to a heat flux of 86 W/cm2. In the next few years, similar units could have heat fluxes of 200 W/cm2 or more, Chen and his colleagues wrote in a new paper in the journal Joule.

“This is why we look at evaporative cooling,” Chen says.

Challenges

Evaporative systems can handle higher heat flux, but getting them right has been a challenge. These systems use porous membranes to increase the surface area for evaporation, but attaining the optimal pore size is challenging. Pores that are too small lead to clogging, Chen says. Too large, and the coolant can form bubbles in the pores and start boiling. Although boiling is under investigation as a possible future cooling technique, Chen says, it adds a lot of instability and complexity to the system. “We are trying to avoid this complication altogether,” he says.

Glass fiber membranes

The researchers turned to glass fiber membranes used in air and water filtration, which naturally form interconnected pore systems. That connected network was crucial to prevent clogging, Chen adds. “You can imagine a three-dimensional network of highways for fluid flow, so one single congested lane will not easily block the entire flow,” he says.

These membranes are commercially produced, so Chen and his colleagues purchased samples and strengthened them with a silane treatment. They then sputter-deposited a thin platinum layer, which they connected to copper electrodes for heating the membrane. They pushed water through the membrane, measuring capillary pressure, permeability, and membrane stability over experiments lasting at least 30 minutes. They found that membranes with pores of about a micron (1 μm) in diameter were ideal. These membranes were able to handle heat fluxes of up to 800 W/cm2. With optimization and engineering, Chen claims, they should be able to go up to 1,000 W/cm2. That level of cooling would be useful for certain high-energy electronics like lasers and LEDs, which can have very high heat fluxes, he adds.

Cold-plate cooling

The researchers are currently working on optimizing the membrane. They’re also working on integrating the membranes into a cold-plate cooling system. A metal cold plate would sit against the electronics being cooled. A coolant, likely a non-conductive dielectric fluid, would run through channels on the cold plate and into the membrane, where it would evaporate. The evaporated coolant would then be captured, condensed and reused in the system.

“We are working on making this prototype of this cold plate for electronic device cooling with the membranes we already have developed so far,” Chen says.

Feng, T., et al., “High-Flux and Stable Thin-Film Evaporation from Fiber Membranes with Interconnected Pores,” Joule, doi: 10.1016/j.joule.2025.101975 (July 16, 2025).

This article originally appeared in the Update column in the August 2025 issue of CEP. Members have access online to complete issues, including a vast, searchable archive of back-issues found at www.aiche.org/cep.